- +86-156 2426 6857

- amy@sdxxhg.com

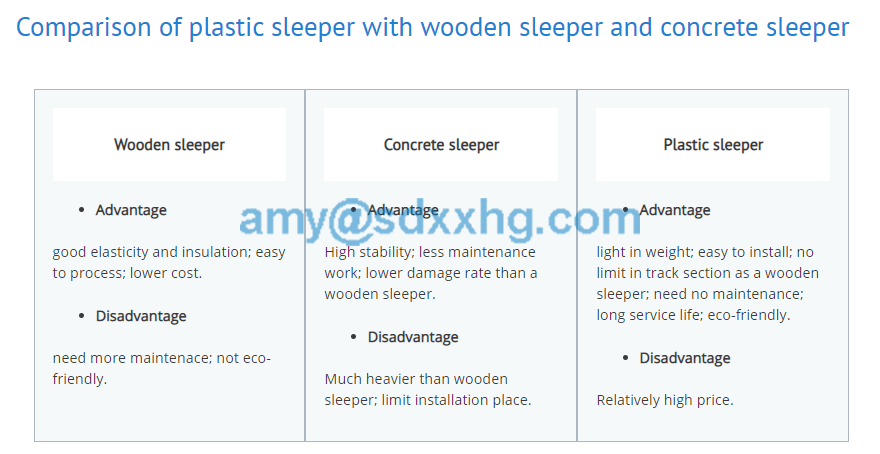

Plastic sleepers with environmental protection,recycling,and corrosion resistance than wooden sleeper more than

three times,longer service life,of the precipice edge of electricity,have good weathering resistance,good absorption

of noise vibration and damping,high crushing strength and chemical resistance of liquid or gas is strong,can also anti-uv,

flood water resistant,within the scope of the -40~70℃,sleeper materials are also not affected by temperature and humidy.

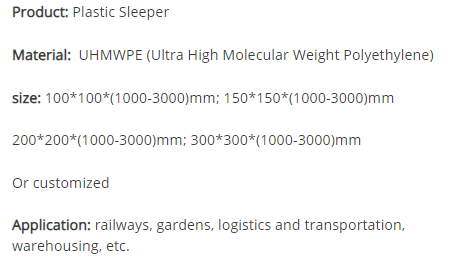

standard size:(1000-3000)mm*100mm*100mm

(1000-3000)mm*150mm*150mm

(1000-3000)mm*200mm*200mm

(1000-3000)mm*300mm*300mm

Any other size can be customized and availabled free drawings.

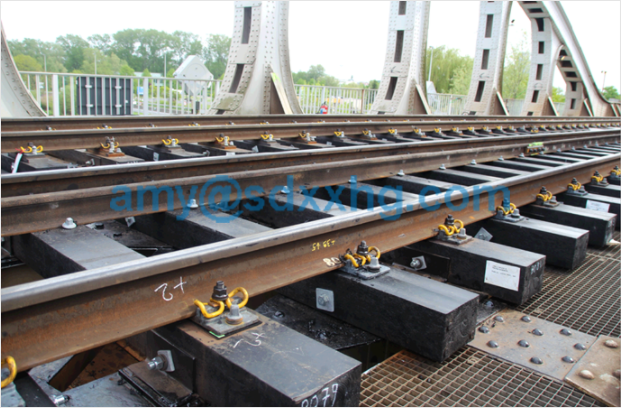

Composite polyethylene plastic sleepers are mainly used in industrial and agricultural production

and daily use, such as trains, railways and manufacturing, large-scale shipbuilding, sea, land and air logistics,

warehouse, automobile manufacturing, aircraft manufacturing, military industry, chemical industry, garden,

mining, construction, machinery,planting and breeding industries and so on.

Advantages relative to wooden sleeper:

1. Toughness does not crack

2. Corrosion resistance: no water absorption and no rot

3. Anti-aging, no moth

4. Long service life

5. Easy to disassemble weight

6. Strong bearing capacity and high impact resistance

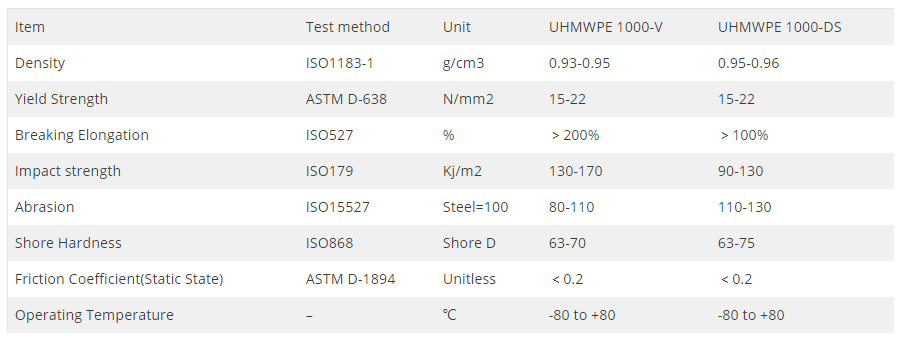

Composite polyethylene plastic sleeper: ultra high molecular weight polyethylene UHMPE material

UHMWPE material has exceptionally low coefficient of friction offering superb sliding properties and is one

of the best plastics for wear/abrasion resistance meanwhile tough and impact resistant even at cryogenic

temperatures. As a result, it is definite that UHMW polyethylene is a wonderful engineering plastic that can

solve many problems that other engineering plastics cannot.